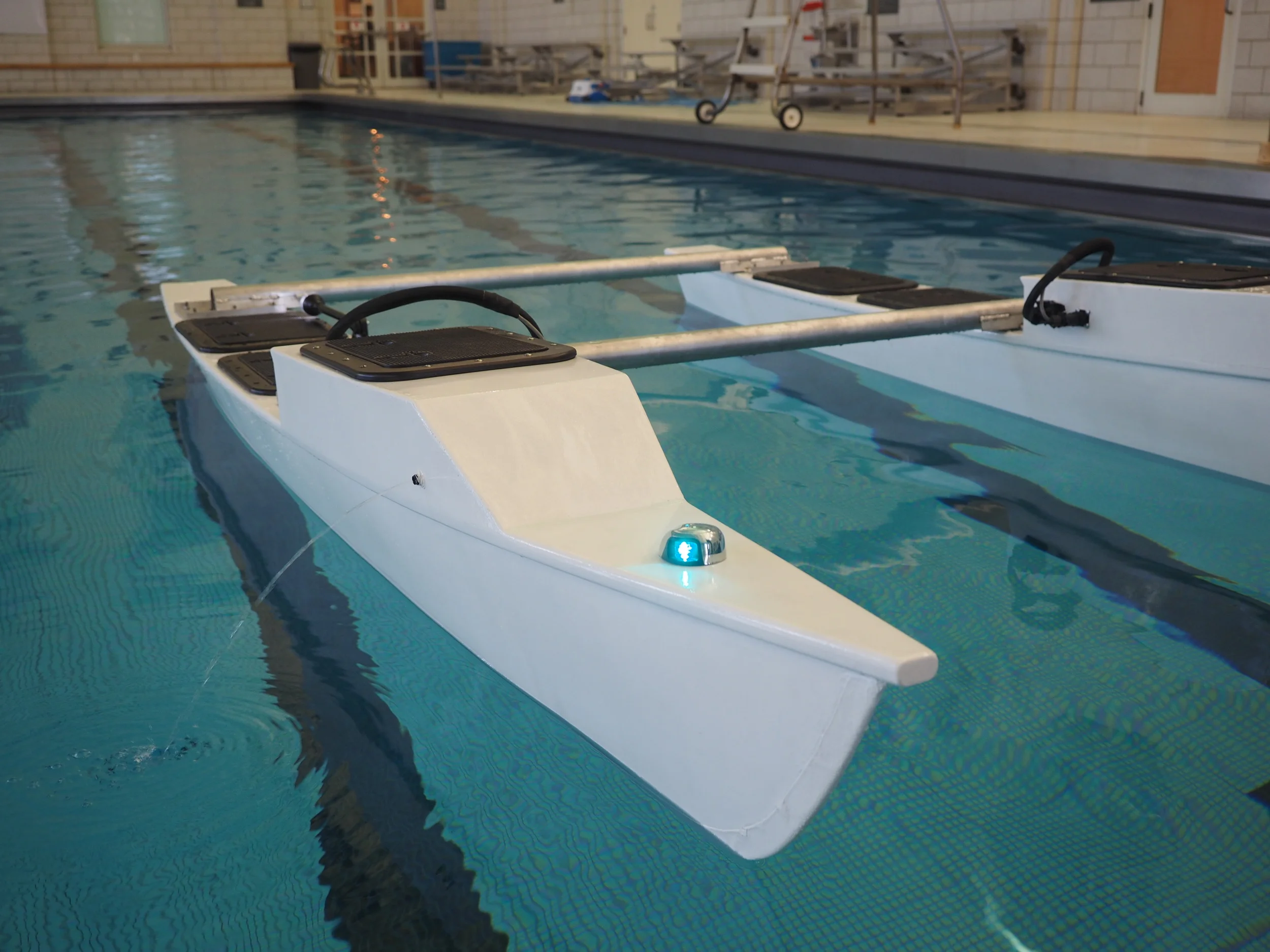

This boat is a long range robotic platform for monitoring oil rigs. The goal of the project was to design and build a long range autonomous platform that could be deployed by a team of two people, transported in a normal pickup truck or SUV, was below 10’ to avoid coast guard regulations, and was very robust and low maintenance.

Staying below a ten foot length was fairly trivial however it does reduce the top speed. A displacement hull’s top speed is, to a large extend dictated by length at the waterline. The multihull design was arrived at as it offered a number of advantages. Having two hulls allowed for a very efficient narrow hull width while still being exceedingly stable. The multihull design also meant that, when disassembled, each piece was fairly light weight which allows for easier deployment by a team of two.

The drive system in the boat has a drive shaft that extends above the waterline which means that there are no seals keeping water out of the boat. This results in fewer items that can fail and made for a very robust, fairly inexpensive drive system. All of the electrical systems are above the water-cooling systems so that leaks would not create shorts in the electronics. We used as many off the shelf components as possible to make manufacturing easier. We did look at buying the hulls off the shelf but couldn’t find such short hulls with such narrow beam widths. Wider boats would not have been able to achieve the exceptional range of this boat.

Once the boat was completed we needed to verify that the platform could take the desired payload. We did our testing in a pool and had two people get on the deck to test past the designed payload. It passed with flying colors.

A video of us load testing set to some fairly epic music.